VIDA Awarded Project - DV014 - Pulsed electric field: an innovative solution for sustainable red winemaking

Comparison of the fermenting must containing untreated (control) and PEF treated grapes of Cabernet Sauvignon after 12 hours of maceration

Duration:

29 October 2019 / 29 October 2020

Summary:

Red wine represents more than 70% of the total wine produced over the world. As compared with the elaboration of white wine, red winemaking requires a stage called maceration-fermentation in which the solid parts of the grape berries remain in contact with the fermenting must for several days (7-10 days). During this stage, polyphenols that are mainly located in the grape skins release to the fermenting must. These compounds are responsible for the sensory properties (color, flavor, astringency, and bitterness) and aging behavior of red wine but also of the beneficial effects for health attributed to the moderate consumption of this product. Maceration-fermentation represents the stage with the highest requirements in energy and manpower during red winemaking.

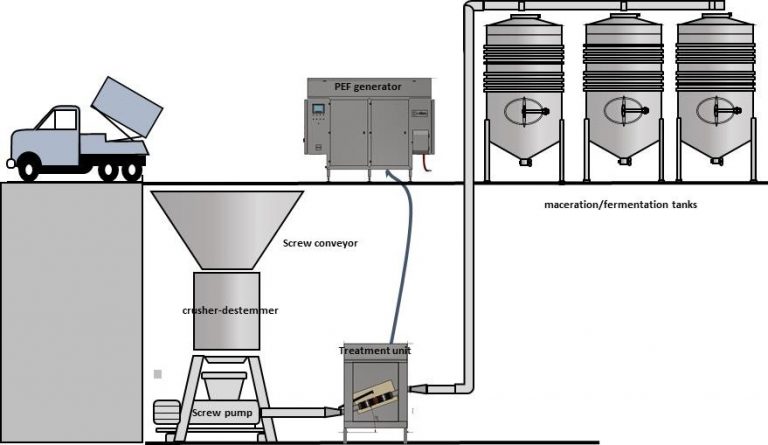

Previous studies conducted at the pilot plant scale have demonstrated that the electroporation of grape skin cells by Pulsed Electric Field treatment (PEF) increases the extraction rate of phenolic compounds during the maceration-fermentation step in red winemaking.

The objective of this project is to demonstrate the benefits derived of introducing PEF processing at industrial scale in a winery in terms of reducing energy inputs and improving the usage of water as a consequence: (i) improving the production capacity of the winery by reducing maceration time, (ii) improving the control of the fermentation temperature and (iii) reducing the periodic pumping of the wine over the skins.

The development of the project that will demonstrate the operability of PEF under the real-life process requirements will facilitate access by wineries to this innovative technology. Savings derived from the introduction of the PEF technology will improve the competitiveness of the wineries in a sustainable and energy-efficient way contributing to maintaining the European rural societies and their lifestyle. Finally, the demonstration of new applications for the PEF technology will increase the sales of the manufactures of this technology and it will lead to job creation in the EU manufacturing sector.

Achieving the objectives of this project require multidisciplinary efforts by a winery (Cooperativa San Juan Bautista, Spain) a manufacture of PEF generator (ELEA, Germany), and a company expert in process optimization (COGNIT, Spain).

Implementation of the PEF technology in a winery

Partners:

COGNITwww.cognit.es

Learn more: www.vidaproject.eu I info [at] vidaproject.eu ( ) I Follow us: @h2020vida

This project has received funding from the European Union’s Horizon 2020 Research and Innovation programme, under Grant Agreement nº 777795.

Disclaimer: The content of this document represents the view of the author only and is his/her sole responsibility: it cannot be considered to reflect the views of the European Commission and/or the Executive Agency for Small and Medium-size Enterprises (EASME). The European Commission and the Agency do not accept responsibility for the use that may be made of the information it contains.