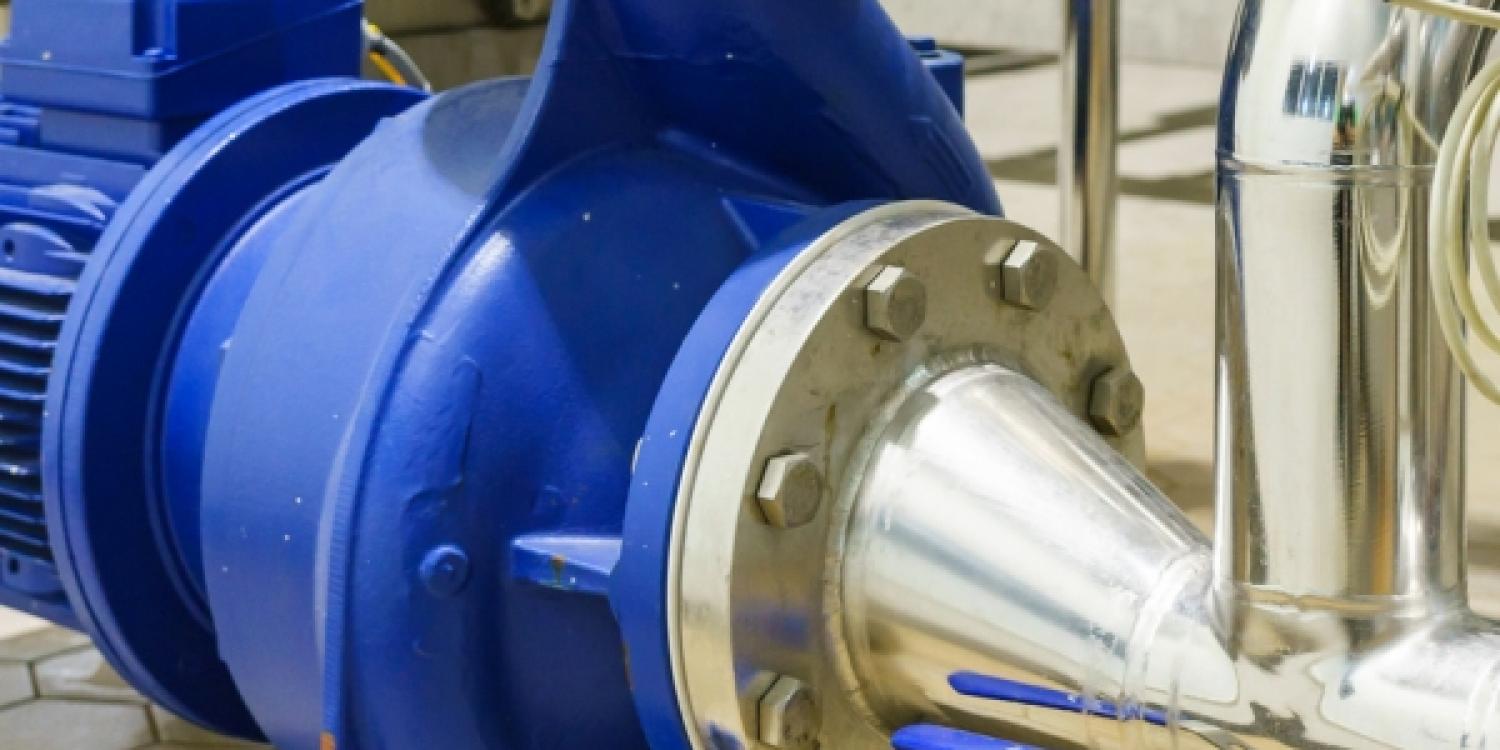

Maintenance of pumps

Information

Maintaining your pumps is not just important for increasing their lifetime and effectiveness, which reduces costs, but also to avoid unexpected breakdowns that can slow or stop production. In most cases, pumps are designed for specific applications, so manufacturer or supplier maintenance and repair guidelines and parameters are needed.

Regular maintenance, including cleaning, greasing, readjusting and checking liquid levels, helps a pump function well for longer. Checklists on optimal performance and key pump reference values and parameters should be drafted for staff to monitor changes. Relevant reference values for a pump are hydraulic power, temperature, and vibrations. If the pump is new or refurbished you should wait at least one hour before you record these reference values.

A common practice to get the most out of machinery is to replace worn parts only when they no longer work. But by that time, the defective part could have damaged other components in the pump. To avoid this, replacing crucial parts in advance is a good practice. Suppliers or manufacturers could provide replacement checklist adjusted for optimal usage, loads and other parameters.

The best way to replace parts in advance is to know their current condition. To calculate which parts to change, it is avisable to regularly (even continuously) monitor component wear and tear, and the whole system. The costs of monitoring process parameters should not exceed cost savings. Therefore, to choose the right maintenance strategy, in light of specific conditions and requirements, you should take into account the following:

- Spare-part costs

- Personnel and training costs

- Costs of soft- and firmware (if needed)

- Costs of storing spare-parts

- Production downtime costs (in the event of unforeseen repairs)