Digital Transition in Upper Austria

Summary: Despite its comparatively recent existence, the Mechatronics Cluster has established itself as a relevant player in the regional industrial ecosystem and is thus an integral part of regional development. In 1990, the first ever mechatronics full degree programme was established at Johannes Kepler University Linz (JKU). In 2003, the Mechatronics Cluster was founded. Since then, the cluster has been working closely with other clusters of the region to increase competitiveness as well as industrial and technological sovereignty. The focus of the Mechatronics Cluster is on business and research, innovation, cooperation, qualification and project initiation, especially in the topics: Advanced Manufacturing, Smart Engineering, Intelligent Production, and Industrial Services. Thus, the Mechatronics Cluster lays the foundation for innovative product developments of its cluster partners from business & research. Through increased participation in European projects, the Mechatronics Cluster also contributes to the development of new value chains for its members.

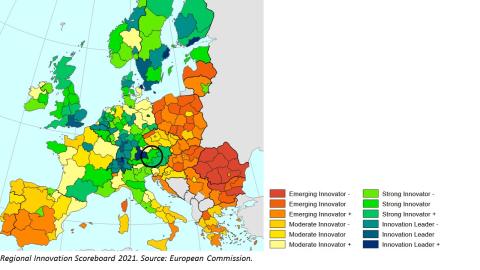

The Upper Austria Region

B4LLS/AdobeStock

B4LLS/AdobeStock

Austria consists of nine autonomous federal states. These each have their own provincial governments, which provide for the provincial administration.

The Upper Austria region is located in the centre of Austria and shares borders with the Czech Republic in the north as well as with Germany (Bavaria) in the north and west. With 14% of its area, Upper Austria is the fourth largest province in Austria. About a quarter of Austria's industrial production and exports are generated by Upper Austrian companies, which makes Upper Austria the leading export, industrial and technology state.

A key strength of the region is its technology development. Mechatronics is a field of strength in Upper Austria with a large number of relevant companies as well as research and development and educational institutions. As a cross-sectional field, mechatronics is relevant to the fields of mechanics, electronics and information technology. The region is also one of the European leaders in the energy sector, with renewable energies accounting for more than 33% of final energy consumption. Upper Austria is also a leader in patent applications (in 2020, Upper Austria had 579 patent applications, surpassing Styria with 476 patent applications and Vienna with 401 applications).

The region is home to a large number of leading companies in various industries: steel and aluminum (Voestalpine, AMAG), vehicle manufacturing (BMW, MAN), mechanical engineering (ENGEL), plastics (Borealis, Greiner) or food (Nestlé). These large companies interact with an innovative ecosystem of small and medium-sized enterprises (SMEs), embedded in an attractive research landscape of various technical colleges and universities. In general, the economic structure of Upper Austria is characterised by a few large lead companies and a large number of SMEs. The region is also distinctive for its high share of R&D spending. Approximately 80% of R&D expenditures in Upper Austria come from the corporate sector and thus largely from Upper Austrian industry.

#UPPERVISION2030 – UPPER AUSTRIA'S BUSINESS AND RESEARCH STRATEGY

The Strategic Economic & Research Programme #upperVISION2030 was developed for the Upper Austrian region for the period from 2020 to 2030. The current programme pursues the goal of focusing on strategic fields of action that will gain in importance in the future and where the greatest leverage is expected. "#upperVISION2030" is based on people who are skilled and educated as well as key technologies and core competencies of the Upper Austrian economy (materials and materials technology, ICT, mechatronics & mechatronic systems).The defined fields of action are intended to contribute to the achievement of the objectives, the increase in competitiveness of regional companies and research institutions, and the creation of modern jobs in Upper Austria. The fields of action are: Digital Transformation (focus areas: Data Driven Enterprise and Secure Systems), Connected and Efficient Mobility (focus areas: Vehicle2X, Automated Driving, Lightweight Construction & Composites, Alternative Drive Systems), Systems & Technologies for People (focus areas: Human/Machine Interface and Medical Material Digital Health)" and Efficient and Sustainable Industry & Production (focus areas: Cross-System Energy Optimization, Raw Material Productivity, Efficient Processes and Production Methods).

The focus in this context lies on smart specialisation and the rapid transfer of research results to commercial applications.

With #upperVISION2030, the province of Upper Austria is realigning its business and research strategy: Away from a rigid programme to an annually adjusted strategy development with a rolling process. Based on the defined fields of action, concrete measures and activities were determined and responsibilities and further partners responsible for implementing the measures were identified. The programme is strategically controlled through an annual review.

INDUSTRIAL ECOSYSTEMS

The Upper Austria region is shaped by seven dominant industrial ecosystems, which all encompass players from the smallest start-ups to the largest companies, from academia to research, service providers to suppliers:

- Mobility, Automotive & Logistic

- Renewable Energy (Energy, Environment)

- Digital (Microelectronics, AI, Robotics, IT)

- Smart Factory (Chemistry, Materials, Plastics)

- Healthcare industries

- Food

- Construction

STRATEGIC CHALLENGES

Strategic challenges, which have been identified and addressed in the region’s business and research strategy #upperVISION2030 are:

1. digital transformation,

2. efficient and sustainable industry and manufacturing,

3. systems and technologies for people, and

4. connected and efficient mobility.

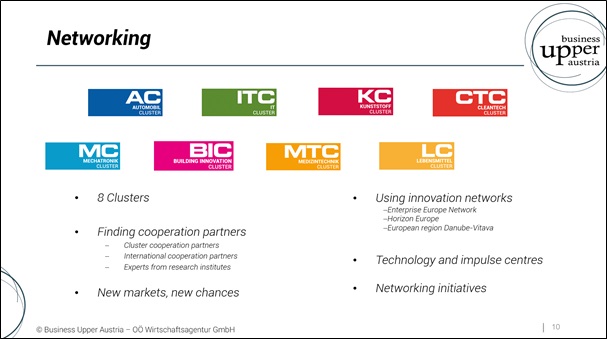

CLUSTER POLICY AND CLUSTERS

An essential component of Upper Austria's economic development policy is the continuous expansion of existing areas of strength with the aim of consolidating the innovative power of companies, particularly through collaboration in clusters. The Upper Austrian cluster landscape is implemented by the “Business Upper Austria” business agency. Clusters in Upper Austria implement innovation-promoting measures ranging from the holistic implementation of cooperative projects and the transfer of knowledge and information to marketing, public relations work and internationalisation activities.

As part of the first strategy programme, the first cluster initiative – the automotive cluster – was founded in 1998. To date, 8 cluster initiatives with around 2200 member companies have joined forces in the association of Business Upper Austria - OÖ Wirtschaftsagentur GmbH (see figure above).

In order to optimally support Upper Austria as a business location and the companies located there, Upper Austrian cluster policy pursues a combination of a botton-up & top-down approach.

Public start-up funding forms the foundation of the top-down approach. In this block, regional calls are crucial, e.g. in 2021 the call Circular Economy, Digital Health and Digital Transformation, in which regional clusters played an important role. The strategic framework for action – strategic programming via RIS-3 strategies – provides the overarching framework for the region's technology and innovation policy and forms another top-down component. The framework builds the strategic basis for the cluster support. Moreover, “innovation alliances” are to be formed, especially on topics relevant to all industries. Within the framework of the bottom-up approach, the cluster management is oriented to the content-related technical needs of the companies and, together with other cluster actors such as the universities, finds forward-looking solutions for the current challenges in the companies.

Further reading:

Business Upper Austria, Cluster and Cooperations: Cluster and cooperations (biz-up.at)

Upper Austria's #upperVISION2030 business and research strategy: uppervision.at

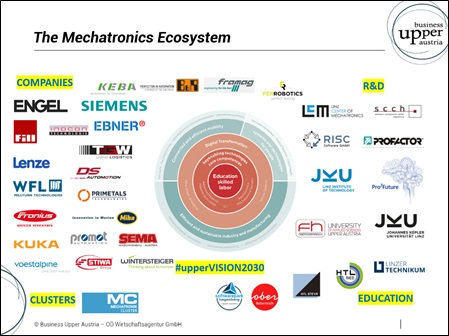

THE MECHATRONICS ECOSYSTEM

Mechanical and plant engineering as well as the metalworking and processing industry have a long tradition in Upper Austria. The topic of mechatronics has a strong presence in the region, and a dense network of innovative companies, research and development institutions, and training and further education facilities in the field of mechatronics has emerged in recent years, which is unique in Europe. Upper Austria has thus developed into the leading competence region for mechatronics.

The member companies of the Mechatronics Cluster employ a total of more than 55,000 people and generate more than 10.8 billion euros in sales in Upper Austria alone. Mechatronics is an economic factor for the state and its people. As a key technology, mechatronics has become indispensable in many industries. Without this combination of mechanics, electronics and information technology, practically nothing would work in the economy anymore.

Upper Austria has also built up large and excellent research capacities in the field of mechatronics (Johannes Kepler University Linz, FH OÖ / Campus Wels and Hagenberg, Linz Center for Mechatronics, OÖ Forschung, CD laboratories such as RECENDT, PROFACTOR, etc.). In addition, Upper Austria is one of the very few regions in Europe that has a continuous education for mechatronics specialists from HTL graduates to FH and university graduates.

Further reading:

Mechatronics hub: https://www.technikstandort.at/mechatronikstandort

Mechatronics hub, Research & Development: https://www.technikstandort.at/mechatronikstandort/forschung-entwicklung

Mechatronics Cluster

skynesher/AdobeStock

skynesher/AdobeStock

The Mechatronics Cluster (MC) is a cross-industry network for companies from the mechanical and plant engineering sector and related industries, such as equipment and apparatus engineering, technology and component suppliers, research and development, and educational institutions.

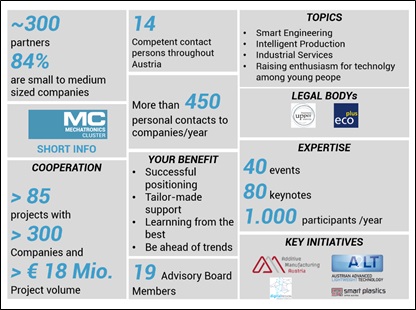

The cluster is an initiative of the states of Upper Austria and Lower Austria. The sponsors of the Mechatronics Cluster are Business Upper Austria - Oö. Wirtschaftsagentur GmbH and ecoplus.Niederösterreichs Wirtschaftsagentur. The Mechatronics Cluster was founded in 2003 with 20 partners. Today the cluster has over 300 members.

The cluster's funding is divided into four areas: ¼ by the state of Upper Austria, ¼ by membership fees, ¼ by fee-based services and ¼ by participation in projects (both national and international). The cluster's budget is between 700,000 EUR and 1,000,000 EUR per year.

MAIN FEATURES

The Mechatronics Cluster has over 300 members from all relevant sectors (industry, research and development, education, government and public administration). In total, more than 55,000 people are employed in the member companies of the Mechatronics Cluster. Due to its unique institutional structure as an extended arm of regional developers in Upper Austria, the cluster's work is based on a triple helix structure (relationships between university, industry and public administration) The cluster management consists of eight qualified employees (7.1 full-time equivalents (FTE)).

The team of the Mechatronics Cluster is supported by an advisory board with regard to the strategic orientation and main topics in the Mechatronics Cluster. This advisory board is composed of representatives from companies, scientific institutions and educational institutions. In this context, a new position paper was drafted at the end of 2021, which outlines how Upper Austria is to become a competence region and an enabler of the digital transformation. The focus here is on five central aspects: #1 Ensuring the core competence of mechatronics at educational institutions in Upper Austria with the aim of securing the future demand for skilled workers. #2 Increasing the digital transformation in companies with the aim of strengthening the global competitiveness of the location. #3 Intensification of technology transfer between research and business. #4 Utilisation of funding opportunities for the implementation of flagship projects. #5 Intensification of networking in mechatronics at the international level in the form of alliances and international collaborations.

The high importance of mechatronics in Upper Austria is also reflected in the current #upperVISION2030 economic and research strategy of the province of Upper Austria, where it is listed alongside materials and materials technologies or ICT as an essential key technology and core competence.

The Mechatronics Cluster carries the Gold Label of the European Cluster Excellence Initiative. In addition, the cluster is involved in many international programmes, in which added value, concrete support services for companies can be derived. Examples of these are:

- RESIST“ ´- REsilience through Sustainable processes and production for the European automotive InduSTry (SMP-COSME-2021-SPP)

- DanubePeerChains (EU Interreg – Danube Transnational Programme)

- Boost4BSO – Boosting CE Business Support Organizations (BSOs) /EU Interreg – Central Europe)

- ECOS4IN – Grenzübergreifendes Ökosystem für Industrie 4.0 (Interreg Central Europe)

- I4EU - I4EU Training Courses (Erasmus+)

SERVICE PORTFOLIO

The service portfolio of the Mechatronics Cluster is very diversified. This includes: development topics, production topics, service topics, international projects as well as events, training and communication.

In the spirit of #upperVISION2030, digital and green transformation plays a central role in the cluster's service portfolio. For example, the international project Innopeer (Interreg) has addressed the topic of Industry 4.0. In this context, comprehensive training offers for companies (from basic technological training to training on new business models) were developed and implemented. As part of another project, companies were supported or accompanied in the digital transformation from analysis to proper implementation. In addition, the Mechatronics Cluster involves companies in international projects to increase their resilience.

In summary, Mechatronics Cluster's service portfolio covers the following aspects:

- supporting internationalisation;

- initiating cooperation with business and science, including start-ups; and

- securing skilled workers as well as training opportunities.

IMPACT

The state of Upper Austria strengthens clusters in the form of cooperation projects. In cluster cooperations, several companies work together – sometimes together with an R&D or qualification institution. On average, between 20 and 35 projects are initiated by the cluster management each year. The cluster management supports members in advising on project ideas, finding suitable project partners, preparing the funding application and handling the submission. This service leads to the positive result that companies that are members of the cluster have a higher R&D rate on average (8.9% in comparison to 3.5%) and are thus more innovative. As a result, Upper Austria stands out as a young and strong research location.

Another positive aspect of the funding is that companies in Upper Austria are increasingly cooperating. Such cooperations offer the individual companies a variety of opportunities that go beyond the goals of the respective cooperation, such as efficient knowledge building, generating new orders and increasing their attractiveness as cooperation partners.

The Mechatronics Cluster, like other clusters in Upper Austria, is involved in various projects whose primary goal is to generate added value for the cluster. For example, the Mechatronics Cluster was involved in the DigiTwin project. The goal of this project was to increase the use and application of digital twins and the associated efficiency across the entire value-added process in mechanical and plant engineering companies (especially SMEs). This is intended to sustainably secure and increase the competitiveness of SMEs. In concrete terms, results from the projects are used to make new technologies tangible for SMEs by means of application examples and to provide information about them.

Another important aspect is regional cross-cluster collaborations in Business Upper Austria. The Mechatronics Cluster entered into new cross-industry cooperations in order to avoid duplicate structures for overarching topics, but also to draw lessons learned from other industries as well as to illuminate the topics from different perspectives. Overarching topics include, in particular, areas such as sustainability, the circular economy and digitalisation. In doing so, the know-how of the individual clusters is used to exploit synergies, but also to break down silos and thus promote thinking in the large cross-industry network.

Cross-industry cluster projects are also initiated in this context. An example is the Austrian Advanced Lightweight Technology Platform. A2LT brings together the expertise of Austrian companies and research centres on the subject of lightweight engineering. In cooperative work independent of sector and materials, innovations are created that exceed the potential of the individual members: innovation through cooperation. A2LT is a joint initiative of the Automotive Cluster, Mechatronics Cluster, Plastics Cluster, industry division of the Upper Austrian Economic Chamber and AC Styria. See a2lt.at.

Lessons Learned and Transferability

The Mechatronics Cluster is the largest cluster initiative in its sector in Austria. All industry segments of the value chain are represented – from mechanical and plant engineering to related industries such as equipment and apparatus engineering, technology suppliers, research and development, and educational institutions. The Mechatronics Cluster has thus established itself as an important player in the regional industrial ecosystem. Established as an integral part of the regional innovation strategy, the cluster is actively used by the public sector to promote regional industrial and thus also digital transformation. Since its inception in 2003, the cluster has contributed to significant employment and revenue growth in the region and initiated various R&D projects primarily focused on digitalisation and upskilling. Activated cross-company know-how exchange and strengthening non-technological and technological innovation competence offered significant added value for the regional ecosystems.

RECOMMENDATIONS

The case of the Mechatronics Cluster and Upper Austria is an example of the development of cluster policy as an instrument of regional economic policy. Moreover, it shows that embedding clusters in a regional economic strategy is essential and provides the necessary framework. The case also shows that cluster initiatives are sustainable instruments. And clusters need to be accepted and consolidated at the local level in order to make cooperation between clusters and regions work.

Finally, the case highlights the importance of cluster initiatives as networks of acting individuals based on mutual and constantly evolving trust. Joint projects (B2B, B2R&D) create long-term and sustainable relationships and increase economic resilience. The Mechatronics Cluster is an example of how the bundling of potentials and competencies leads to an increase in the innovative strength and international competitiveness of the cluster partners. Particular attention is paid to the needs of SMEs.