The SmartStock Duomo 2.0 project ends

-

Industrial research project that aims to obtain knowledge in various key areas for the management of automated warehouses and related management systems.

-

Creation of a new embedded system software and hardware development for the Akoma warehouse

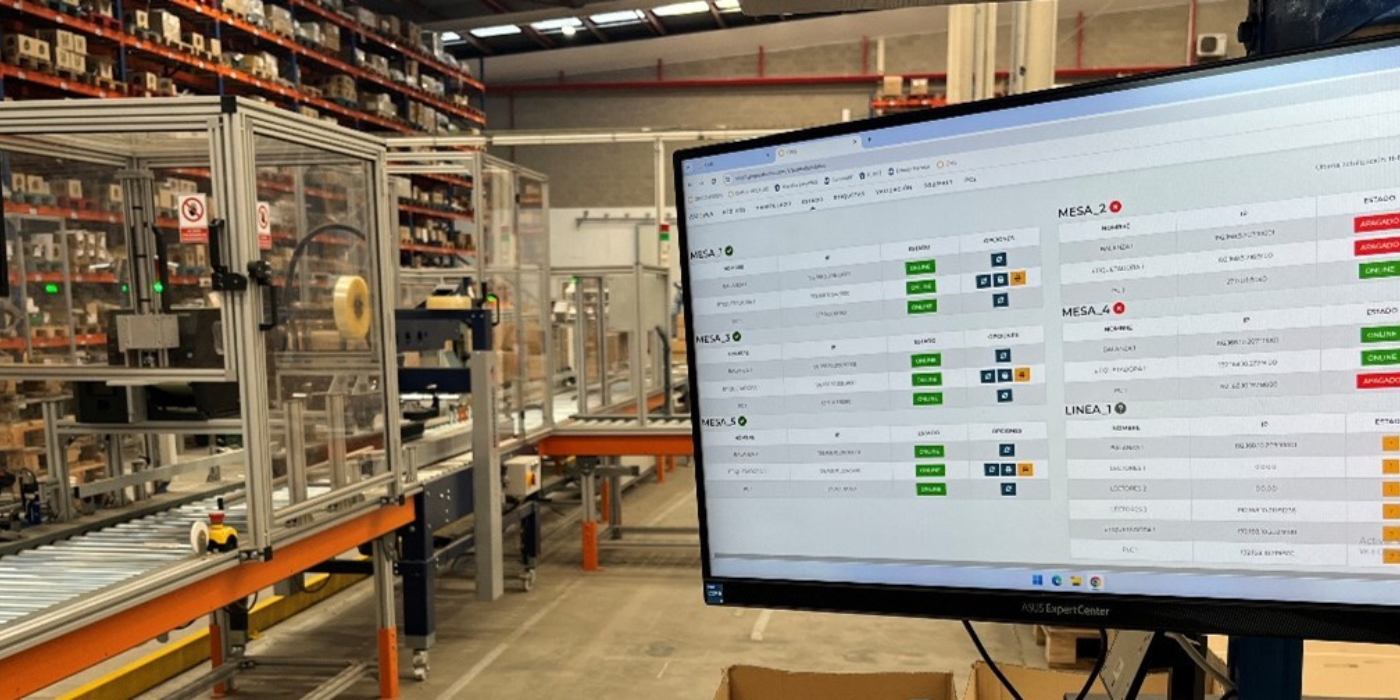

SmartStock Duomo 2.0 is an industrial research project that aims to gain knowledge in several key areas of automated warehouse management (I would try not to repeat what has already been put in the headline), efficient order management, integration of warehouse management software, the development of inventory control sensors and the implementation of electronic control and data acquisition systems. Space- and energy-efficient automated storage systems have been designed and implemented, as well as the integration of order management systems and efficient and scalable warehouse management systems. The project is divided into two phases, a first of industrial research and a second of execution. In the research phase, experience was improved in configuring automated transportation systems to optimize the flow of products within the warehouse and streamline order processing; The physical management of the automated warehouse and inventory and supply management were strengthened; New knowledge was acquired in the design and development of robust and long-range electronic systems to connect sensors to visualization and data analysis platforms, and knowledge of screen printing and its application in the development and prototyping of new sensors was expanded. inventory control. The execution phase focused on the software and hardware development of embedded systems that directly impacted the Akoma warehouse with greater automation and digitalization in order management and warehouse management. It also represented an improvement in the automation of Product Inventory Control thanks to: a low-cost, high-efficiency inventory control sensor based on screen printing technology, which is capable of accurately measuring the number of stored parts, reducing costs. costs associated with manual inventory monitoring; and a robust, long-range data acquisition and control electronics system that allowed the sensor to be connected to a data visualization and analysis platform. The company Embeblue, specialized in the development of electronics for the Internet of Things and Industry 4.0, has been in charge of the electronic part of sensor control and wireless communication and the results obtained have been a device that measures the stock of material through the weight and sends the data to the cloud. The company Rotimpres, specialized in the design and manufacture of printed electronics, has been in charge of the manufacturing and characterization of the weight sensors and flexible control electronics and the results obtained have been a sensorized blanket that allows real-time control the stock in the picking area. The Twentic company, specialized in business digitalization and custom application development, has developed software for the comprehensive management of logistics warehouses and production lines to optimize the handling and shipping of orders. The system covers everything from order receipt to packaging and labeling automation, improving handling and logistics. It integrates with external devices such as PLCs, barcode readers, sensors and printers to optimize and accelerate logistics operations. The Akoma company, specialized in commercial and industrial handling, logistics and storage, has been in charge of implementing the transformation, automation and carrying out the testing and validation of the Smart Pressure sensor in its facilities. The results obtained have been the digitalization of its warehouse, with automated picking and classification technologies, order management and the automation of product inventory control. Finally, Packaging Cluster has led and managed the project and Functional Print has been in charge of the communication and dissemination of the project. This project has been a finalist for the Factories of the Future Award, at the Advanced Factories 2024 conference, in the category of Best Research and Development project, as a project that visualizes the transformative impact through the use of machine learning technologies in manufacturing and production processes industrial. The SMARTSTOCK DUOMO 2.0 project, budgeted for €324,779, has been financed with €257,024 by the Ministry of Industry, Commerce and Tourism through the support program for Innovative Business Groups (AEI), within the framework of the Recovery, Transformation Plan and Resilience, with the aim of improving the competitiveness of small and medium-sized companies.